Aluminum is a widely used material in many industries due to its excellent qualities such as strength, durability, and workability. These qualities make it perfect for machining and producing precision parts. One of the most used forms of aluminum is aluminum blocks which are molded into different shapes and sizes to meet various machining requirements. In this article, we will explore what aluminum blocks for machining are, the advantages they offer, and why they are an excellent choice for manufacturing.

What are Aluminum Blocks for Machining?

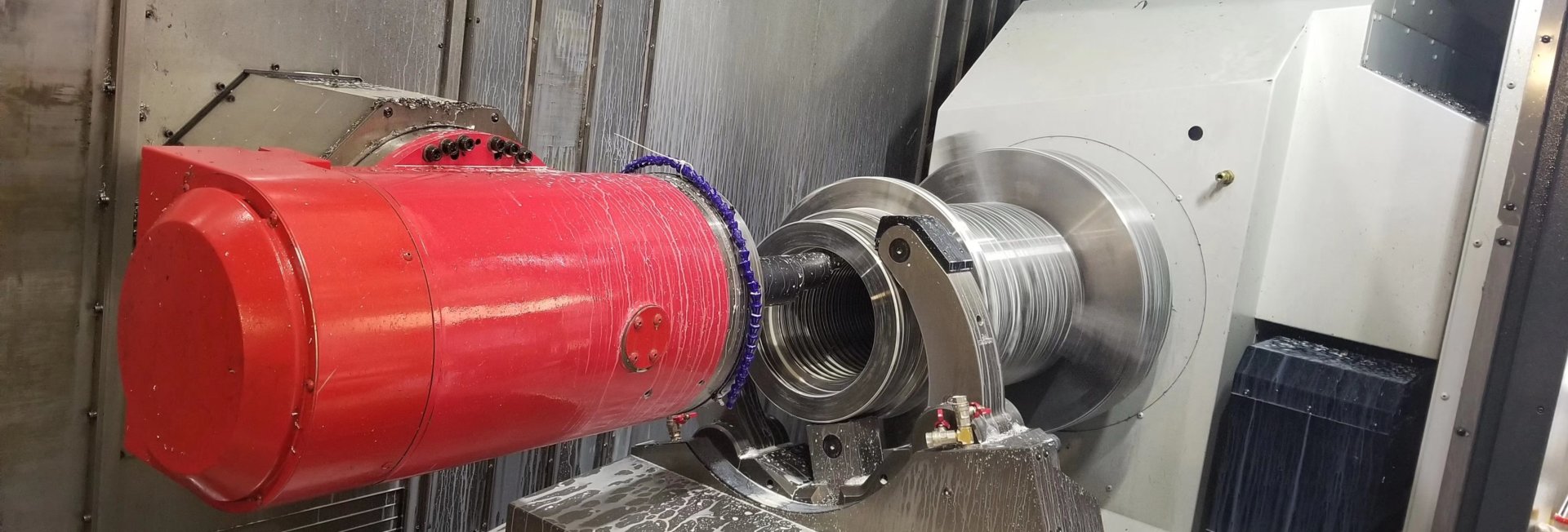

Aluminum blocks for machining are aluminum-based materials that are designed to be used in machining and production operations. These blocks are made from a high-quality blend of aluminum alloy which makes them strong, durable, and resistant to wear and tear. The aluminum blocks are molded into different shapes and sizes to meet the needs of different machining applications. Once formed into the desired shape, the aluminum blocks undergo machining processes such as milling, drilling, turning, and grinding to create finished parts.

Advantages of Aluminum Blocks for Machining

Aluminum blocks for machining offer a wide range of advantages which make them the go-to material for many machining applications. Some of the advantages of using aluminum blocks for machining include:

Workability: Aluminum is an easy material to work with, making it perfect for machining operations. It can be easily formed, shaped, and cut without losing its inherent strength.

Strength: Aluminum blocks for machining are strong and durable, resisting wear and tear and able to withstand a range of operating conditions.

Versatility: There are many different grades and alloys of aluminum available, allowing for the production of parts with varying properties such as temperature resistance, corrosion resistance, and thermal conductivity.

Low Cost: Aluminum is one of the most cost-effective materials for machining and production due to its abundance and low manufacturing cost.

Why Aluminum Blocks for Machining?

Aluminum blocks are an excellent choice for manufacturing due to their many advantages. They can be used in a wide range of applications, including aerospace, automotive, medical equipment, and other high-tech industries. Aluminum blocks for machining are also ideal for producing prototypes, as they offer the perfect balance of strength, workability, and cost-effectiveness.

Choosing the Best Aluminum Blocks for Machining

When choosing aluminum blocks for machining, it is important to consider the properties that will best suit the desired end product. Factors such as strength, hardness, conductivity, and corrosion resistance are crucial to the success of the final part. By working closely with a trusted machining supplier, it is possible to select the best aluminum blocks for any application.

Conclusion

Aluminum blocks for machining are an excellent choice for any manufacturing project, offering a range of advantages such as strength, durability, and workability. Choosing high-quality aluminum blocks for machining is the key to producing finished parts that meet the precise specifications required for any given application. With the right supplier and proper selection of materials, aluminum blocks for machining can help businesses take their production to the next level.